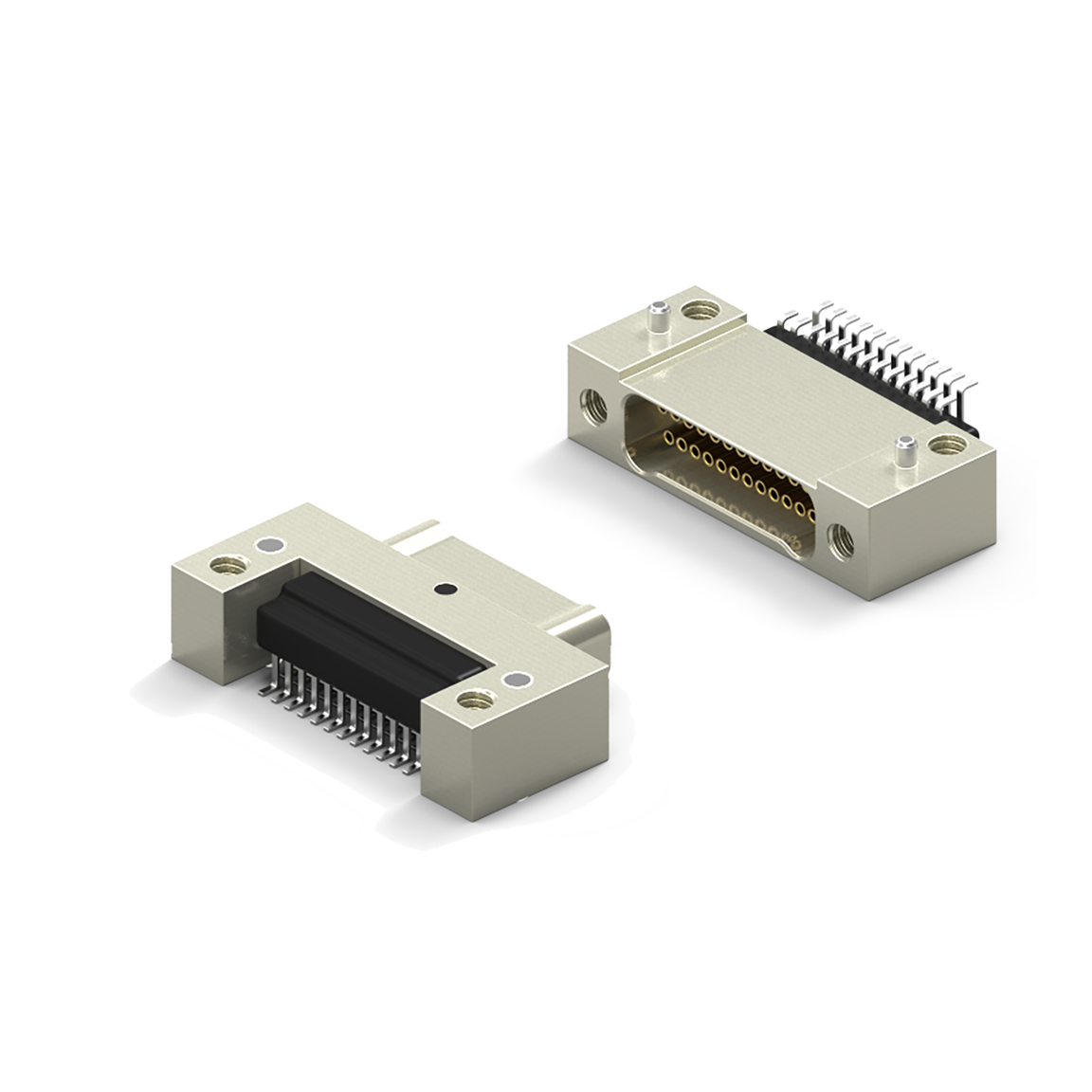

Electronic systems and subsystems have continuously shrunk in size and weight while still requiring high-performance specifications. Consequently, surface-mounted connectors have evolved in kind, from Military Circular connectors and D-Subminiature to Micro-Ds to today’s top technology: Nano-Ds. Despite the abundance of suppliers in the market, quality and production issues have persisted as they try to balance size constraints vs performance requirements.

As board-level connectors get smaller they become more difficult to process. Hand soldering or the use of a hot bar is still common in low volume production, leading to diminished quality control and low production rates. Size-related difficulties notwithstanding, Nano connectors still need to meet the robust performance requirements to withstand the harsh, high shock and vibration environments in which they will need to perform.

Our competition uses a two-piece design, crimping a bus wire to the end of the contact. The bus wire is then formed into a shape to be directly soldered to the surface of the board. Due to the tight spacing, small wire diameter, short length, and multiple row configurations, consistently forming the bus wires into the correct geometry is incredibly difficult. Coplanarity, or 3-dimensional alignment, of the surface leads suffers from such designs and often results in unstable solder joints. Quality issues can lead to expensive rework or field recalls. Mission-critical, high shock, and vibration applications cannot afford to have these design flaws in their systems.

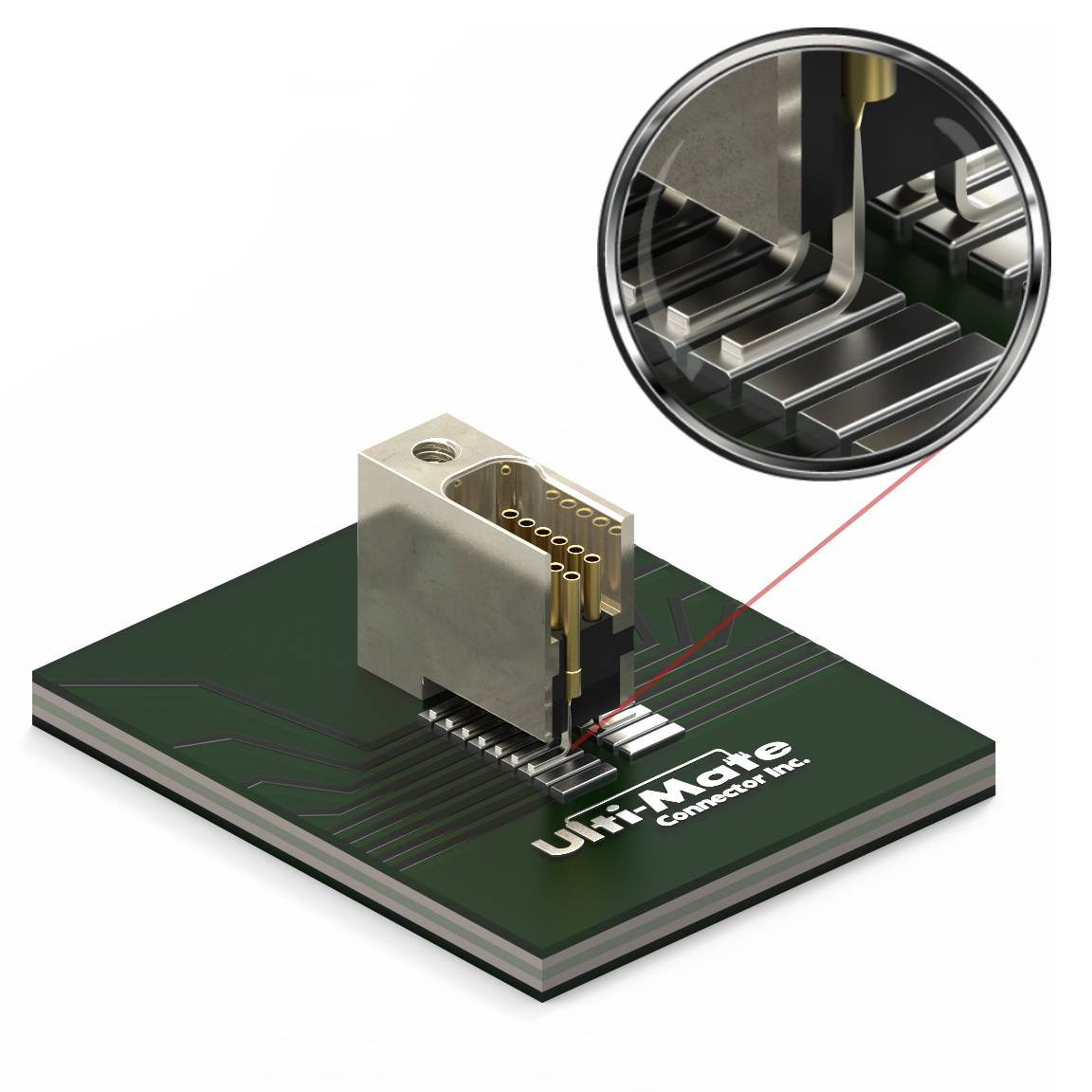

Winchester Interconnect Micro, formerly known as Ulti-Mate Connector, uses a one-piece design and offers the most reliable solution for today’s requirements. Stamped and formed from a single piece of metal, our design eliminates most of the production variability from using a bus wire in a surface mount Nano-D. As a result, Winchester Interconnect Micro surface mount Nano-Ds have an industryleading controlled coplanarity of -0.001” to +0.003”

The rectangular shape of the surface mount lead also offers improvements with solderability, as high-quality solder fillets form much more easily with a rectangular object compared to a round object. Together, tightly controlled coplanarity and rectangular leads can reduce the amount of solder paste required to form solder fillets, reducing the chances of shorts occurring in the field.

Furthermore, the removal of a crimp connection reduces contact resistance, preventing increased temperatures, energy loss, and potential failure points.

Beyond the Nano-D construction, our surface mount Nano connectors are packaged in specially designed tape and reel or plastic trays - formed specifically for the product - to ensure quality control through rough transit. This type of packaging can support pick and placement by automated handling equipment using vacuum nozzles. Parts not picked can merely have the top of the tray put back on and secured, and parts can go back into stock.

Our customers approach us with a recurring story: process and production engineers struggle with competitors’ parts, often unbeknownst to the design engineers. Rework and field failures are all too common - one customer reported 62% rework on all installations. Working with production and design engineers, Winchester Interconnect Micro, provides a solution that meets all of the application requirements and eliminates rework associated with low-quality coplanarity, solderability, and manufacturability. Winchester Interconnect Micro Nano-Ds have outperformed in a battery of high-requirement qualification tests from countless customers across multiple industries.

We encourage design engineers to talk to production engineers about problems they may be experiencing, particularly with Nano-Ds. Winchester Interconnect Micro, and more broadly Winchester Interconnect, is committed to improving reliability and manufacturability for our customers’ products through our innovative designs and technologies.