| Materials and Finishes |

| Signal Pin Contacts |

C17200 Beryllium Copper per ASTM B194 |

| Signal Socket Contacts |

C26000 Brass Alloy per ASTM B135 |

| Contact Plating |

Gold Plating per ASTM B488 |

| Shell |

6061-T6 Aluminum per SAE-AMS-QQ-A200/8 or 300 Series Stainless Steel per ASTM A582 |

| Shell Plating |

Electroless Nickel per SAE-AMS2404, or Cadmium per SAE-AMS-QQ-P-416 or Black Anodize per MIL-A-8625 or Passivated per AMS2700 |

| Insulator Material |

LCP(Liquid Crystal Polymer) GLCP-30F or PPS per MIL-M-24519 GST-40F |

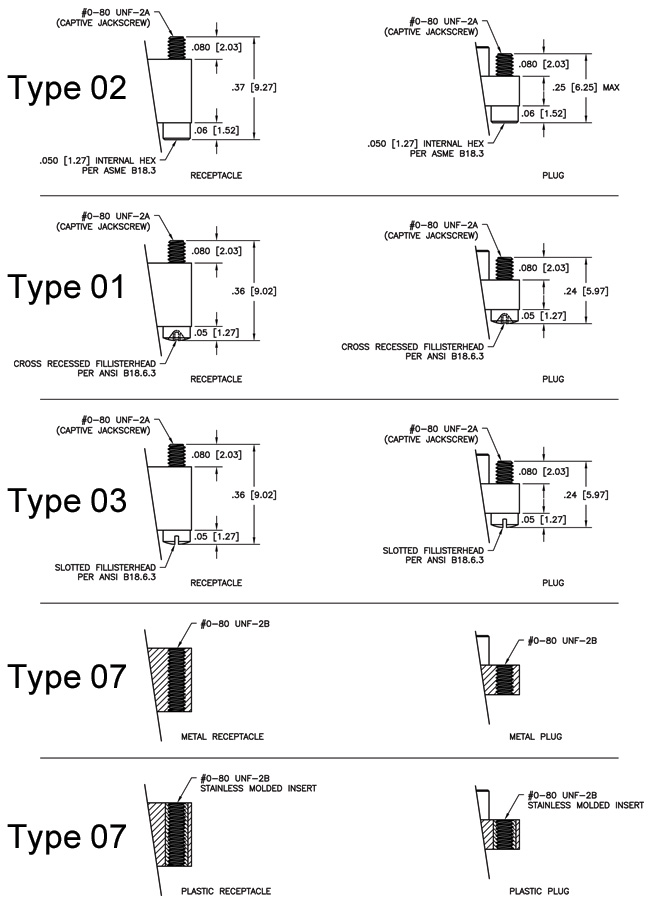

| Hardware |

300 Series Stainless Steel per ASTM A 582/A582 or ASTM A 581/A581M, Passivated per SAE AMS-2700 |

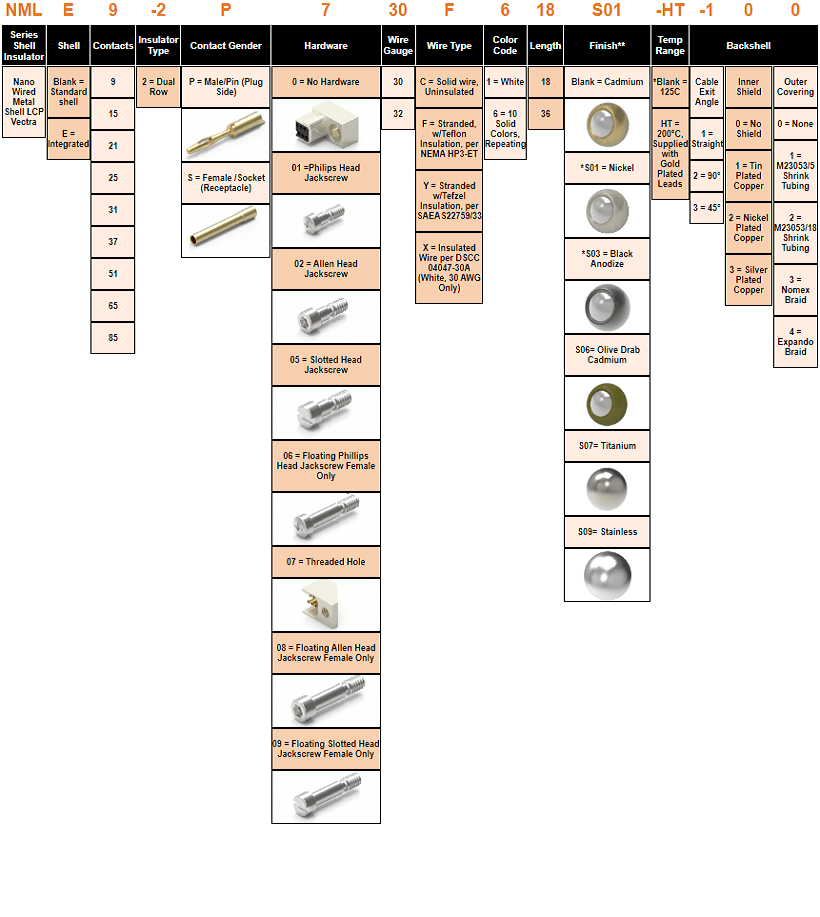

Our How To Order tab allows users to configure the Winchester Engineering # for

Nano Integrated BackShell

.

Please confirm the part number(s) you selected with our customer service department prior to placement of order.

*Indicates Preferred Standard

**Consult Factory for other plating options

*** Leave blank if no Mounting Option is required (F01- Float Mount is not available for size 100)